Green Hydrogen: The Fuel of the Future

Is Empowering a Zero-Carbon Emissions Combustion Turbine with Hydrogen Viable?

Hydrogen (H2) can make a significant contribution to clean energy transition in the power generation sector. The hydrogen-fueled combustion turbine (CT) is a carbon-neutral technology that eliminates longstanding carbon emissions, particularly when integrated with renewables and H2 gas production technologies. This article addresses the technical and economic challenges constraining the large-scale production of hydrogen, the need for new infrastructure for storage and transportation of hydrogen, and introduces the many CT combustion and ancillary system design issues and upgrades facing CT OEMs when burning H2.

Growing Hydrogen Market

Natural gas is the most common gaseous fuel used in the global power generation market. It will continue to fuel many new CTs and combined cycle plants (CCPs) in the future. Many countries prefer natural gas over other fossil fuels as it produces fewer air emissions. Compared to coal, the combustion of natural gas produces 50% less CO2 emissions per unit of fuel consumed.

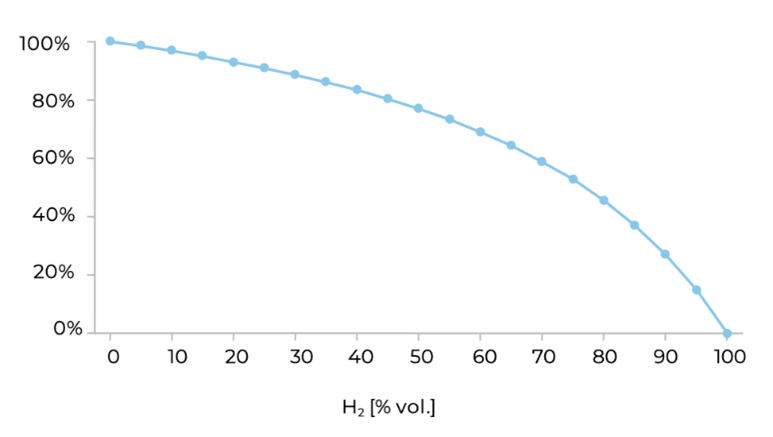

Further reduction of CO2 emissions from combusting gaseous fuels is possible if natural gas is mixed with a renewable gas before entering an existing CT. Renewable gases include green hydrogen, biogas, and syngas. Decreasing the CH4/H2 ratio (by volume) does reduce the carbon intensity (CO2 emissions), although it is not directly proportional. A mixture with 100% H2 has a carbon intensity of 0%; however, a mix with 50% H2 has a carbon intensity of approximately 80%. Thus, immediate reductions of carbon emissions are possible with current CT combustion technology when burning even small amounts of H2. With relatively minor changes to the combustion system, a typical CT can burn up to about 30% H2 by volume, which correlates to an 11% reduction in the amount of carbon in the CT emissions.

The carbon intensity of CH4/H2 mixtures

Many CT OEMs are committed to evolving their product lines to burn 100% renewable gases by 2030, with a combined cycle gross thermal efficiency of 65+%. Fast-acting, high-efficiency combined cycle plants burning renewable gases form a perfect partnership with slower-response and less predictable renewable generation, such as wind and solar energy. However, CTs must remain flexible in operations, enable fast-starts, and demonstrate fast ramp rates to respond to intermittent renewable operation and changing grid conditions. For example, surplus renewable electricity produced during off-peak hours can be rechanneled to generate H2 stored for later consumption during high-demand periods. Thus, H2 production using surplus renewable generation may be considered as a carbon-neutral energy storage technology. The combination of hydrogen-enabled CT technologies coupled with the production of renewable gases will “future proof” the modern electricity grid.

In many markets, the critical challenge for commercialization will be to generate enough H2 through renewable energy, such as through off-shore wind and solar, in a cost-competitive manner. There is no point in producing H2 with electricity produced by fuels with a carbon footprint in a hydrogen-based economy.

Burning hydrogen poses numerous challenges. Capital expenditure (CapEx) items such as electrolyzers and air separation units incur high costs, which vary by region. For instance, in Europe, CapEx ranges from $1 to $1.5 million per megawatt. Additionally, electricity, constituting 80% of operational expenditure (OpEx), currently costs about $80 per megawatt-hour. Consequently, projects are often not financially viable without funding, remaining heavily reliant on subsidies and government support to justify their economic feasibility. However, the verdict on this matter is still uncertain. What are your thoughts? Feel free to email us with your insights, and we'd be delighted to engage in a constructive, data-based discussion